Check out our app!

Explore more features on mobile.

Insulation and Drywall Installation: Ensuring Thermal Efficiency and Smooth Walls

Insulation and drywall form the critical thermal and visual envelope of your building. Research shows that proper installation can reduce energy costs by 20-30% and increase property value by up to 6%. This comprehensive guide explores professional installation techniques, material selection, and expert strategies to ensure your walls and ceilings deliver maximum efficiency, comfort, and aesthetic appeal.

[Image: Professional Insulation and Drywall Installation in Progress]

Key Steps in Insulation and Drywall Installation

These are the critical tasks involved in creating an energy-efficient and aesthetically pleasing interior:

1. Insulation Material Selection and Planning

Choose the appropriate insulation materials based on the building’s climate zone, wall assembly type, and performance goals. This crucial planning phase establishes the thermal performance that will affect comfort and energy costs for decades.

- R-value requirements: Select insulation with proper R-values based on climate zone (R-13 to R-21 for walls, R-30 to R-60 for attics) according to IECC standards

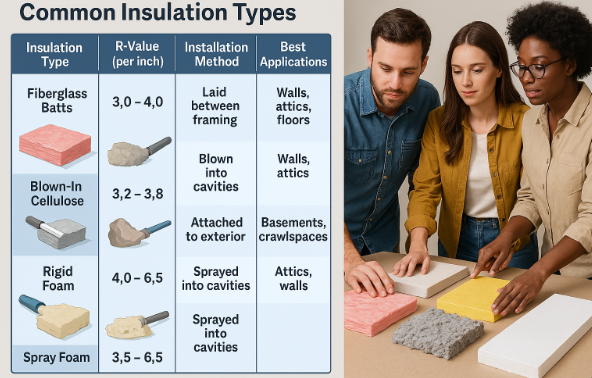

- Material comparison: Evaluate options including fiberglass batts (R-2.9 to R-3.8 per inch), mineral wool (R-3.0 to R-3.3 per inch), spray foam (R-3.7 to R-6.5 per inch), and cellulose (R-3.2 to R-3.8 per inch)

- Vapor barrier strategy: Determine appropriate vapor retarder placement based on climate (interior-facing in cold climates, exterior-facing in hot-humid climates) to prevent moisture accumulation

2. Air Sealing and Envelope Preparation

Seal air leakage points and prepare the building envelope before insulation installation. Air sealing can be more important than insulation itself, as it prevents conditioned air loss and moisture migration through the building assembly.

- Critical junction sealing: Apply caulk or spray foam at top/bottom plates, around window/door rough openings, and at penetrations, targeting maximum 3 ACH50 (air changes per hour at 50 Pascal pressure)

- Recessed fixture treatment: Install air-tight IC-rated (insulation contact) fixtures or build sealed boxes around non-IC fixtures, maintaining minimum 3″ clearance from insulation

- Rim joist insulation: Seal rim joists with 2″ closed-cell spray foam (minimum R-10) at foundation/floor transitions to prevent major air leakage at these vulnerable points

3. Wall and Ceiling Insulation Installation

Install insulation in walls, ceilings, and floors to enhance thermal efficiency and reduce energy costs. Proper installation technique is as important as the insulation material itself for achieving rated R-values.

- Batt installation: Install batts with full contact against all six sides of cavity, cut precisely to fit around obstructions, with no compression or gaps exceeding 2% of insulated area

- Blown insulation application: Install loose-fill to proper density (minimum 1.5 lbs/cubic foot for cellulose) with depth markers every 300 sq ft to verify consistent coverage

- Spray foam application: Apply at proper temperature range (65°F-85°F surface temp) with 2″ maximum thickness per pass for closed-cell and 5″-6″ per pass for open-cell to prevent improper curing

4. Drywall Layout and Hanging

Secure drywall sheets to the structural framework, ensuring proper alignment and fit. The hanging phase establishes the foundation for smooth, seamless finished walls that will influence the entire interior appearance.

- Drywall selection: Use 1/2″ drywall for walls (5/8″ for fire-rated applications), with moisture-resistant (MR) or fiber-reinforced panels in bathroom wet areas

- Layout strategy: Plan horizontal sheets with tapered edges meeting at 48″-54″ height, staggering vertical seams by minimum 16″, and avoiding four-corner intersections

- Fastener spacing: Install screws at 12″ on center for ceilings, 16″ for walls, set 3/8″ below surface without breaking paper face, minimum 3/8″ from edges

5. Taping and Mudding

Apply joint compound and tape over seams and screw holes to create a smooth, continuous surface. Proper taping technique creates walls that appear seamless under various lighting conditions and finish types.

- Tape application: Embed paper tape (not mesh for flat joints) in 3″-4″ bed of all-purpose compound, with proper feathering 8″-10″ wide from center of seam

- Corner treatment: Install metal or paper-faced metal corner bead on outside corners, secured every 8″, with three progressively wider coats of compound

- Coating sequence: Apply three separate coats (tape coat, fill coat, finish coat), allowing 24 hours drying time between applications in normal conditions

6. Finishing and Texturing

Sand, texture, and prime the drywall, preparing it for painting or other final finishes. The quality of finishing determines whether drywall installation appears professional or amateurish under normal lighting.

- Sanding technique: Use 150-220 grit sandpaper with light pressure, feathering edges 12″-16″ from seam center, with pole sander for ceilings and hand sanding for detail work

- Texture application: Apply consistent texture (orange peel, knockdown, or smooth) using proper pressure (25-30 PSI for orange peel) and technique for uniform appearance

- Corner treatment: Use special attention at inside corners, creating crisp, straight lines with specialized corner tools and light sanding

Who Handles Insulation and Drywall Installation?

These installations require specialized professionals with proper training and experience:

- Insulation Contractor: Specializes in thermal envelope systems with knowledge of building science principles, vapor control, and air sealing techniques for maximum energy efficiency

- Energy Auditor: Evaluates building envelope performance using blower door testing and infrared imaging to identify thermal weaknesses and verification of air sealing effectiveness

- Drywall Hanging Crew: Skilled specialists who measure, cut, and install drywall panels with precision, creating the framework for seamless walls and ceilings

- Taping and Finishing Specialists: Highly skilled artisans who apply joint compound, tape, and textures to create smooth, flawless wall surfaces that appear continuous

- Acoustic Ceiling Installer: Installs specialty ceiling systems including acoustic panels, coffered ceilings, or specialty designs requiring specific expertise

- Building Inspector: Verifies that insulation meets energy code requirements and that fire-rated assemblies are properly installed according to design specifications

Time & Cost Estimates

The timeline and budget for insulation and drywall installation vary based on project size, material selection, and finishing complexity. Here are detailed estimates for each major phase:

| Installation Component | Estimated Time | Estimated Cost | Key Value Points |

|---|---|---|---|

| Material Selection & Planning | 1–2 days | $500–$1,800 | Ensures optimal thermal performance for specific climate |

| Air Sealing & Preparation | 1–3 days | $800–$2,500 | Prevents air leakage that can reduce efficiency by 30% |

| Insulation Installation | 2–5 days | $2,500–$8,000 | Creates thermal barrier for energy savings and comfort |

| Drywall Hanging | 2–4 days | $2,000–$6,000 | Establishes the base for interior wall finishes |

| Taping & Mudding | 3–5 days | $1,800–$4,500 | Creates seamless appearance between panels |

| Finishing & Texturing | 2–3 days | $1,200–$3,500 | Provides final surface preparation for paint/wallpaper |

| Total Estimates | 11–22 days | $8,800–$26,300 | Complete thermal and interior wall system |

These cost estimations provide a general guideline and cover a range from basic to mid-tier builds. They may not reflect costs for high-end or luxury projects. For more precise estimates, consult with professionals based on your specific requirements.

Cost-Saving Tips

Optimize your insulation and drywall investment with these expert strategies:

- Strategic insulation allocation: Invest in higher R-value materials for attics (greatest heat loss area) while using standard insulation for walls, optimizing thermal performance without increasing total costs by 15-20%

- Hybrid insulation approach: Use spray foam at critical air sealing points (rim joists, penetrations) combined with less expensive batt insulation for general areas, achieving 90% of spray foam performance at 60% of the cost

- Larger drywall sheets: Use 54″ wide or 12′ long sheets where possible to reduce the number of seams by 25-30%, decreasing finishing time and material usage

- Two-coat finish system: Consider using setting-type compound for first coat and lightweight all-purpose for second coat, eliminating the need for a third coat in non-critical areas

- Strategic scheduling: Coordinate insulation and drywall installation during off-peak seasons when contractors offer 10-15% discounts to fill schedule gaps

- Material waste reduction: Create detailed take-offs and optimize panel layouts to minimize cuts and waste, potentially saving 8-12% on material costs

Summary: Your Insulation and Drywall Action Plan

1. Prioritize Air Sealing Before Insulation

Focus on comprehensive air sealing of all penetrations, gaps, and transitions before installing insulation. Even small air leaks can dramatically reduce the effective R-value of insulation and compromise the thermal envelope’s performance.

2. Select Materials Appropriate for Your Climate

Choose insulation R-values and vapor barrier strategies specifically designed for your climate zone. The wrong approach can trap moisture within walls, while the right strategy optimizes both comfort and long-term durability.

3. Invest in Quality Drywall Finishing

Allocate sufficient time and resources for professional drywall finishing, as this visible element affects the perceived quality of your entire project. Proper taping, mudding, and sanding create walls that appear seamless even under challenging lighting conditions.

Proper insulation and drywall installation forms the foundation of your building’s comfort, energy efficiency, and interior aesthetics. Following these professional guidelines ensures that your walls will provide decades of performance while maintaining their appearance.

Complete Your Insulation and Drywall Project With Confidence

Track Your Progress: Monitor your insulation and drywall milestones with our interactive tools

Stay Notified: Receive alerts for material deliveries, inspection schedules, and drying time requirements

Step-by-Step Guidance: Follow detailed instructions on air sealing, insulation installation, and drywall finishing techniques

Reduce Stress: Keep all specifications and inspection records organized in one secure location

Whether you’re building a new structure or renovating existing spaces, professional insulation and drywall installation are essential for energy efficiency, comfort, and interior aesthetics. Explore our Step-by-Step Builds, Step-by-Step Buys, and Step-by-Step Invest resources for more expert guidance.

When building your own home, always do your due diligence. Consult the professionals you’ve hired—such as your architect, subcontractors, or engineers—and confirm that your work complies with all local building codes and inspections required in your country, state, or province. Builds and Buys is for educational purposes only. Always verify with licensed professionals.

How to Drywall a House (Professional Crew)

In this Building a House From Start to Finish Episode we hire a drywall crew to come in and drywall our entire house. We document the entire process and provide the step by step process and tools you will need if you are doing this on your own. We split up the process into three phases: 1. Hanging the Drywall 2. Taping & Mudding the Drywall 3. Sanding the Drywall. For each phase we break down the process until we have our own fully drywalled house!

Check out more informative Videos

How to Choose and Install Insulation | How To Anything

Not all insulation is made the same, but which one should you use? Depending on your needs, Taylor will walk you through the 4 main types of insulation, fiberglass batts, foam panels, spray foam, blown-in-insulation, and the best applications for each.

Check out more informative Videos

News And Knowledge

Stay informed with the latest trends, insights, and updates in the real estate world.

Your Tools

Access your tools to manage tasks, update your profile, and track your progress.

Collaboration Feed

Engage with others, share ideas, and find inspiration in the Collaboration Feed.